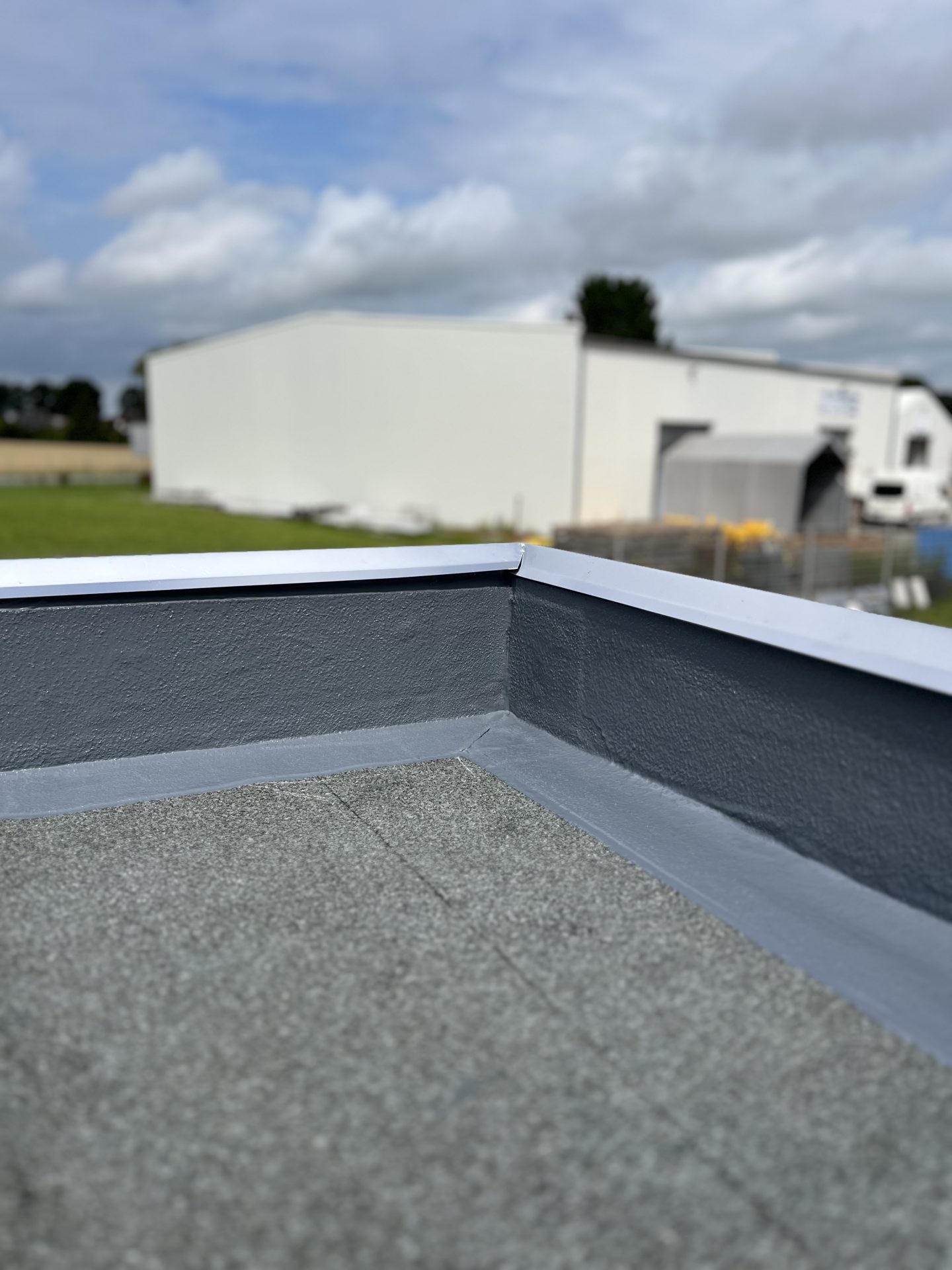

WIDOSEAL-LF 1K

WIDOSEAL-LF 1K is a solvent free, one component liquid waterproofing for flameless application on flat roofs and balconies, detailed connections, structural waterproofings and special solutions. The material basis of WIDOSEAL-LF 1K is an SMP.

The material has been tested at the highest performance levels in accordance with the European guide lines for liquid applied roof waterproofings (ETA-24/0499 according to EAD 030350-00-0402).

In addition, it has been tested according to PG-FLK and PG-FBB. WIDOSEAL-LF 1K achieved the corresponding general building inspectorate test certificates for structural waterproofing of areas in contact with the ground. Thus, it may also be used at floor to ceiling windows and in basement areas.

Basis

SMP

Reinforcement

Polyester fleece G120

Consumption (2,2 mm layer thickness)

approx. 2,8 kg/m²

Curing time (at. +20°C/50% humidity)

approx. 24h,

Rainproof after approx. 45 min.

Water vapour diffusion resistance factor (µ)

832

Basic colour

Grey (dark) / White / Anthracite /

Special colours available on request

Fire Classification

E according to DIN-EN 13501-1

and resistant to flying sparks and radiant heat BROOF(t1) according to EN 13501-5

Packaging units

3,50 kg, 7,00 kg and 14,00 kg

Minimum working temperature

+5°C

Temperature resistance

-30°C bis +90°C

Cleaning in fresh condition

WIDOPAN-Cleaner

Storage

If container is kept closed and storage temperature held constantly below + 25°C the product may be used for up to 6 months.

During processing and curing, the material is nearly odour-free. The EMICODE-classification of EC 1 Plus confirms the low odour impact.

Polyester fleece G120 is used as reinforcement. The reinforcement determines the breaking strength and elongation at break and ensures an even layer thickness. The overlap of reinforcement layers must be at least 5 cm. The overlap to other materials is to be determined for each case separately, but should not be less than 10 cm.

Surface preparation

WIDOSEAL-LF 1K adheres without priming to many surfaces which are dry (max. 5% dampness), free from grease/oil, loose parts and other materials which may lower the adhesion. Surfaces which require priming as well as general information regarding the surface preparation may be found in our references for priming. You may also seek advice from our application engineers.

Applicaton

There is a foil on the material within the bucket which has to be removed before using the material. Then, the material needs to be stirred thoroughly with a slowly rotating

agitator. Then, 2/3 of the waterproofing material is applied onto the prepared surface with a paint roller. Afterwards, the Polyester fleece is embedded into the wet material and the remaining 1/3 of material is applied onto the fleece using the paint roller. Once the container has been opened, the material should be used up swiftly. Should the material form a thin firm layer, this can easily be removed and the remaining material may be used up.

Additional coatings may be applied within 24 hours without any further preparation. After 24 hours, the surface needs to be roughened before a further layer may be applied. Alternatively, areas which may need additional coatings, may be sprinkled with quartz sand whilst the first layer is still wet.

Further details, especially regarding hazard statements, security advices and measures in the event of fire can be found in the safety data sheet under sections 2, 4, 5, 6, 7 and 8.

Please also refer to our instructions on priming and to our technical information sheets

Download pdf

Additional products

Main products

WIDOPUR-Primer FTE

WIDOPUR-Primer FTE WIDOPAN-Polyester Fleece G 120

WIDOPAN-Polyester Fleece G 120 WIDOPAN-Stone carpet

WIDOPAN-Stone carpet WIDOPERL

WIDOPERL